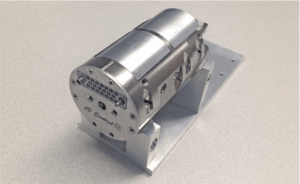

Power Supplies

High Voltage and Low Voltage Power Supplies, High Voltage Assemblies

- Custom designed to your specifications

- CAN-BUS to interface options for high voltage supplies

- Multiple standard and non-standard input voltages

- Best in class size, efficiency, regulation, lowest ripple, and power density

- Excellent thermal management options

- Efficiency up to 92%

- Compact and lightweight to meet SWaP requirements

- Full MIL-spec operation

- Excellent performance for dynamic and static loads

- Exceptional quality utilizing dB Control’s core technologies, in-house manufacturing processes (encapsulation and pressure curing) and testing (RF, environmental, HALT and HASS)

- Specialized Contract Manufacturing and Build-to-Prinit Services

Reliable Power When and Where You Need It

- Airborne, shipboard and ground-based mission-critical operations

- Radar, electronic warfare and communications

- Radar transmitters, SAR, multimode radars, data links

We Qualify Multiple Military Programs Every Year

Airborne

Shipboard

Ground

- MIL DO-160 MIL-STD 461/704E and MIL-STD 810E guidelines

- Shock and vibration (gun fire, non-gun fire, airborne, shipboard, helicopter)

- Various cooling conditions (conduction cooled -54 °C to +100 °C, ECS and RAM air up to +96 °C; liquid-cooled PAO, glycol; and Built-in Heatsink Fan Cooled)

- Severe environmental conditions (temperature shock, temperature cycling, solar radiation, humidity, fungus, rain, wind and ice, snow, sand and dust, salt atmosphere)

For specific applications, contact info@dbcontrol.com.

PRODUCT DESIGN

High Voltage Power Supplies

Core technologies

- High voltage assembly, power converter, and control/monitor logic circuits designed in house

- Transformers, Inductors and high voltage modules built in house using standard and proprietary RTVs, epoxies and encapsulation processes

Module designs for multiple input/output configurations

- Integrated with TWT output devices

- Prime power capabilities for 28 VDC, 270 VDC and 115 VAC to 380 VAC single phase or 3 phase

- Output Voltages to 50 KVDC

- Grid and FE modules for high PRFs to CW

- Interface Logic Options (Discrete, Serial, Ethernet)

- Compliant with MIL-STD-704 and integrated EMI Filter to meet MIL-STD-461

Low Voltage / High Current Power Supplies

- Integrated with GaAs or GaN solid state output devices

- Single outputs: 6 VDC to 48 VDC up to 70 A

- Multiple outputs: +/- 5 VDC, 12 VDC, 25 VDC

- Prime power capabilities for 28 VDC, 270 VDC and 115 VAC to 380 VAC single phase or 3 phase

- Multiple high voltages input: 2KV, 4.5 KV

- Various control and interface capabilities: FSK, serial and discrete, CANBUS, RS-485

- Output voltage sequencing, voltage hold-up timing requirements

High Voltage Assemblies

Custom High and Low Voltage Transformers for Military and Commercial Amplifiers:

- Winding

- Full vacuum and pressure encapsulation

- Hi-potting and test

- Tested at high altitude

Custom High Voltage Modules, Connectors and Cables

- Assembly

- Full vacuum encapsulation

- Hi-potting and test

- Tested at high altitude

Special-Purpose Power Supplies & Towed Decoys

dB-2348 Towed Decoy | DC-to-DC converter, +1500VDC to +10VDC at 43Amps

dB-2347-01 Airborne Power Supply | 1500VDC Input, 6.4VDC Output at 68Amps

MANUFACTURING SERVICES

Assembly

- All operators are J-Standard-Certified with extensive military product experience working to Class 3 Standards

Magnetics (Winding)

- Proprietary epoxy formulation and winding techniques

- All HV transformers hi-potted and tested at altitude

Potting (Encapsulation)

- Proprietary material formulations minimize stress on components and maintain voltage stand-off in harsh environments

- Custom vacuum and pressure chamber procedures

Test (Sub Assembly and Top Level)

- All encapsulated modules subjected to hi-pot and burn-in stress screening

- Multiple test stations with equipment rack configurations for quick set up and adaptability

- Variety of temperature ovens, chill plates, to simulate environmental conditions

- Automated ESS test stations

- Technicians trained in both DC and RF testing

- Test and Project Engineering support on all programs

IN-HOUSE TESTING

- Temperature, altitude, combined temp/alt and HALT/HASS chambers

- MIL-STD 704 and limited 461 capabilities

- Hot and cold operational testing (conduction, ECS, liquid & ambient/altitude)

- Vibration and shock

QUALITY AND CERTIFICATIONS

- Full AS9100D and ISO 9001:2015 certification including design and development

- AS9102 Revision A Compliant (First article inspection to IAW current aerospace standards, documentation using official AS9102 forms/format)

- Entire assembly & QA workforce certified for PC-A-610E and J-STD-001E Class 3

- A2LA-accredited equipment calibration

- IPC/EIA J-STD-001 Class 3 certified for soldering electrical and electronic assemblies

- Inspected to IPC-A-600