Guest Author: Jose Gonzales, Production Engineering Manager

Major integrators must decide whether to use solid state or traveling wave tube devices to amplify RF signals used in radar, electronic countermeasure (ECM), electronic warfare (EW), datalink and communication systems. In some cases, it boils down to SWaP-C (Size Weight, Power and Cost with instances where C can also stand for Cooling). The question still remains: SSA or TWT? But why not use both? In the first of this blog series on modern day microwave power modules (MPMs), we’ll discuss how both SSAs and TWTs can be used in a single transmitter to make up a microwave power module (MPM).

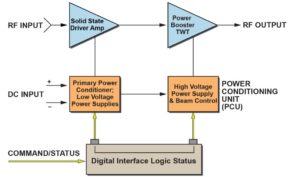

Block Diagram of Typical MPM

The SSA devices and TWTs of the 1990’s aren’t the same today. Solid state amplifier devices have improved due to new materials (including GaN devices). Likewise, TWTs are becoming more innovative with manufacturing processes and designs. In fact, TWT manufacturers are spearheading major improvements in efficiency, reliability and design for applications where long life and reliability are crucial. Some TWT manufacturers consistently push for more output power, increased bandwidth and higher frequencies beyond Ka-Band.

The great thing about modern MPMs? They take full advantage of these improved SSA and TWT technologies. And they do it by integrating both into a compact, lightweight package. The RF signal path consists of a solid-state driver amplifier and a short-length booster TWT (typically seven inches long or shorter), specifically designed for use with a lower-voltage power supply. Any gain reduction that occurs from shortening the TWT helix length is compensated by the driver solid-state amplifier. This results in maintaining the gain in the RF chain. The power-handling capability, bandwidth, efficiency, and heat-tolerance capability of the TWT is fully utilized in this type of design. Field proven MPMs offer performance in the following areas:

- Overall Efficiency greater than 35% (typical)

- Operating temperature ranges -55°C to +75°C

- Spurious and Phase noise performance

- Altitude up to 70K feet

- Both CW and Pulsed application

- Wide Band options

- Low noise power density

The most reliable MPMs have also been fully qualified to perform under very harsh environments and conditions in airborne, maritime and ground mobile applications. In the next blog post in this series, we’ll discuss overall efficiency improvements, power capabilities, and design/manufacturing requirements of these modern MPMs.